Not finding a position in your chosen field after graduating from university or college can be discouraging, if not demoralizing. For Arek Swito it was the first step to a career in construction.

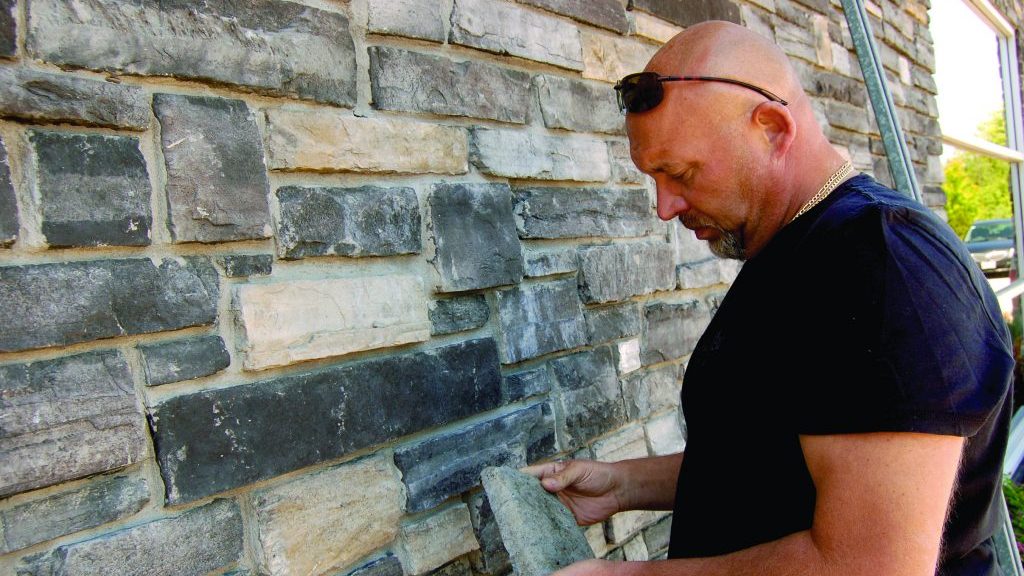

The 47-year-old Georgetown, Ont. resident is the founder and co-owner of Exteriors In Motion, an installer of exterior thin stone on both commercial and residential buildings.

In its almost 15 years of existence the company has built up an inventory of long-time clients in this somewhat niche business. Some of those clients include Cara Foods, Moxie’s Restaurants, and Marriott Hotels.

In 2017 Exteriors In Motion installed approximately 780 square metres of synthetic stone and another 139 metres of natural Muskoka Granite on the exterior of the Guild Inn as part of a major refurbishment of the east-end Toronto landmark facility.

It was invited to take on an interior project this year, but had to decline because of other jobs.

The road to that success, though, has been long and steep. Swito studied business management at Seneca College, but when he graduated in the early 1990s the country was locked in a deep recession and opportunities in that industry were very limited. So, he started a trucking company and drove trucks for about eight years.

“It was crazy,” says Swito, in a reference to the long hours and uncertainties of long-haul trucking. Eventually he left the business.

His entry into construction was through his father-in-law who owned a small contracting company.

“I helped him renovate a warehouse and one thing led to another.”

That included the creation of Exteriors In Motion in 2004 with partner Bartek Syrek, a long-time associate. Their first big contract was the Lora Bay, a high end cottage development in Thornbury, Ont. The stone manufacturer actually provided the on-site instruction.

When asked if mastering the art of thin stone installation was a learning curve in those early days, Swito replies: “It’s always a learning curve, even after all these years.”

Thin stone installation is not a licensed trade and there is no definite name to distinguish it from other trades.

Thin stone is a challenging product which you have to know inside and out

— Arek Swito

Exteriors In Motion

“It’s not masonry — masons don’t want to have anything to do with it.”

Nevertheless, a considerable amount of knowledge and skill is required and there is a constant two-way flow of information between manufacturers and installers on technical innovations and what has been learned on the jobsite, he says.

“Thin stone is a challenging product which you have to know inside and out — especially in Canada where cold air is trying to get in (the building) and hot air is trying to get out which can lead to condensation.”

Installing it successfully requires strictly following the manufacturer’s instructions and careful on-site visits to evaluate projects and to conduct measurements in which to submit a successful bid, he says.

Like any other trade, thin (or decorative) stone contractors must wrestle with a litany of challenges including the weather, manpower availability, and timing — especially as they have to wait until the exterior walls have been prepared by other subcontractors.

“We’re usually the last trade on site and then we have to meet the construction manager or general contractor’s deadlines.”

Meeting those deadlines requires working throughout most of the winter as long as temperatures don’t deep below 0 C, which is the critical threshold for the cement to dry. With the exception of extremely frigid periods, such as the kind which slammed most of Canada last Christmas, that temperature level can usually be sustained by working under heated tarps.

“It can get warm enough you can work in a T-shirt,” says Swito, noting workers shouldn’t get careless and leave the enclosure without putting on a coat.

As is the situation on any construction site, safety is a major concern, notably the proper use of the heaters which must operate around the clock until the cement dries. There are two types of heaters, propane and diesel, and both have pros and cons.

“Propane heaters are flammable, loud, and not very friendly to use. But, they are more economical to rent than diesel ones.”

Operators are required to hold a valid Record of Training certificate and Swito requires all his employees to take training courses which are available through manufacturers or rental firms. Also mandatory is working at heights training.

At any one time the company’s workforce ranges from between five to 15 people, although four are long time employees.

Last fall the company branched out into new territory when it secured an agreement to be the exclusive North American dealer for a European stone manufacturer. It takes about six weeks from the time the stone is ordered until it can be delivered on site.

“European quality of products are much higher than in North America,” says Swito, in explaining why he decided to offer the stone.

Recent Comments

comments for this post are closed