Imagine a safety inspection app so powerful that it can tell the difference between an image of a construction worker wearing a properly secured safety harness and one that isn’t — and then identify exactly which company health and safety policy that the incident involves. That’s not some tale from the far-flung future, but describes the off-the-shelf capabilities of PCL’s newly launched HSE Hazard Safety Inspection app. Leveraging the promises of artificial intelligence (AI), machine learning and the expertise of PCL staff, this app is set to become a whole lot smaller.

“We began to build the app using our health, safety, and environmental operating procedures (HESOPs) and our manual as the basis,” says Jim Barry, vice president, health, safety, & environment with PCL Construction. “We’re not building up from the regulations, because our own HESOPs are always more stringent than the legislative requirement.”

It takes a company with the size and history of PCL to effectively train the app. Just to begin developing such an app required a library of between 500 and one million pictures as a visual database. PCL’s development team and data scientists searched through literally millions of jobsite photos, inspection reports and massive data files that were used to teach the app to look for significant factors in the images.

The app also needed to ensure that the efforts of each employee tasked with an inspection were fully logged and acknowledged, that the app would be secure and that it could work quickly enough to digest geo-tagged images and transform them into actionable intelligence.

“Within a jobsite image, the app recognizes a harness, a lanyard, a leading edge and the position of the workers in relation to that edge,” says Barry. “In the worker’s toolbelt it might see a tool that isn’t properly tethered that represents a danger to workers below. As it became more intelligent the app was able not only to identify the hazard or deficiency, but also what part of the manual and which HESOP was associated with it as it highlights the relevant phrasing on the screen.”

The app also assesses the severity of each hazard, assigning it an A, B or C — with A representing the most serious hazard, presenting an imminent threat.

“The algorithm tells the person completing the inspection how serious the problem is,” says Barry. “It’s moving so fast that it can educate the person performing the inspection, presenting the reference to the associated HESOP to drive the lesson home. And there’s always that visual reference in the photo to create a permanent record of the hazard in case there’s a need for further discussion or verification. That picture is worth a thousand words in communicating a hazard to a partner, a foreman and other workers.”

If the employee performing the inspection disagrees with an assessment, they can override it. That would lead to a jobsite discussion and possible further programming of the algorithm.

“If the app is wrong, we would provide it with enough information so that it would properly understand that hazard going forward,” says Barry. “But to date, the algorithm has been bang on. Using all of this information, we can itemize and categorize safety hazards and offset the likelihood of recurrence by developing a targeted action plan.”

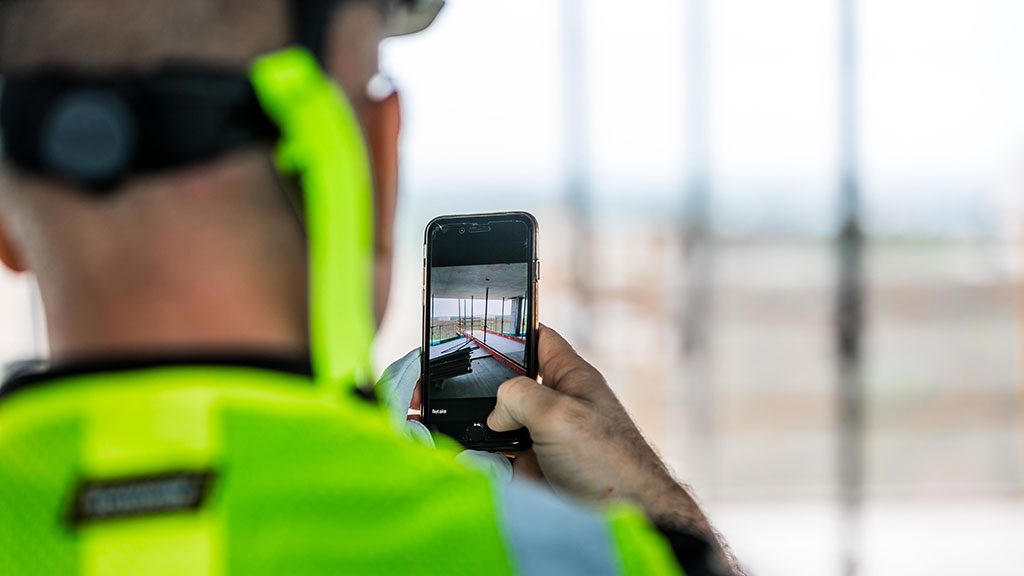

After several years of development, the app was piloted in 2018 and graduated to general use within the company in fall 2019. PCL employees simply download the app to their smartphone or camera-equipped device and conduct inspections as usual, capturing images of the inspection as they go. It’s already paying dividends, easily identifying jobsite hazards and becoming more adept at its task as it’s used.

Inspections are also leaner as filling out paper forms or webforms designed to log inspection reports have been completely eliminated—the app provides a complete inspection log along with visual confirmation. A report on an infraction is also sent to all stakeholders the moment it’s entered into the system.

The safety app is just one of the digital technology initiatives developed by PCL. Other industry-leading applications developed and embraced by the company include the implementation of cognitive Machine Learning (ML) for on-site concrete truck detection, and Job Site Insights™ which uses multiple sensors on a project to monitor heat, humidity, flooding and more in real time, all on a single-pane viewing platform.

“Our CIO Mark Bryant and his team are very technically savvy and have encouraged PCL to embrace technology to the fullest,” says Barry. “They’re always looking for an edge to make our company better and share those benefits with everyone around us — our trade contractors, our partners and our clients. Working on the HSE Hazard Safety Inspection app, the entire tech team and the executive management team in general have been very supportive.”

While the app has won converts among all workers, younger workers in particular have embraced the cutting edge technology that allows them to complete their inspections faster, more efficiently and more accurately.

“Once they get hold of the app, you’ll never get it away from them,” says Barry. “That’s good, because when they’re using the app, we seem to learn a lot more and learn faster.”

PCL is currently investigating the possibility of creating a portal that will allow selected trade partners and clients to access the functionality of the app under special agreement. The potential also exists for the app to be further developed and sold to other companies as an independent product.

“New technology provides us with so much opportunity to be lean, and to access and process real-time data,” says Barry. “With this app it also allows everyone to get home safe at the end of the day and live their lives to the fullest.”

This content is sponsored by PCL Construction in collaboration with ConstructConnect® Media. To learn more about PCL, visit www.pcl.com.

Recent Comments

comments for this post are closed