Large-scale cannabis production is still in its infancy on this continent with no state-of-the-art production template yet identified.

So when MYM Nutraceuticals Inc. set about planning its landmark $200-million, 1.5-million-square-foot medicinal cannabis greenhouse facility to be built in Weedon, Que., it hired what its CEO Rob Gietl says is an all-star team of greenhouse designers, builders and growers to create new standards in production.

MYM recently issued a spate of announcements introducing LEED-qualified greenhouse constructor David Leslie to build the greenhouses, ICORE as the general contractor, microgreen specialist Joel Lalancette as the master grower and veteran mass-production greenhouse expert Casey Houweling to oversee the set-up of greenhouse operations and best practices in growing and harvesting.

Houweling, based in Delta, B.C., said in an interview he has been brought on for two years, with this first year devoted to planning and design and next year to be spent on construction.

“I look forward to working with these other people,” he said. “No one person has all answers.

“It is a very young industry and there is a lot to learn yet. The ability to put the brainpower together and come to conclusions at the end of the day, that is the way to do it.”

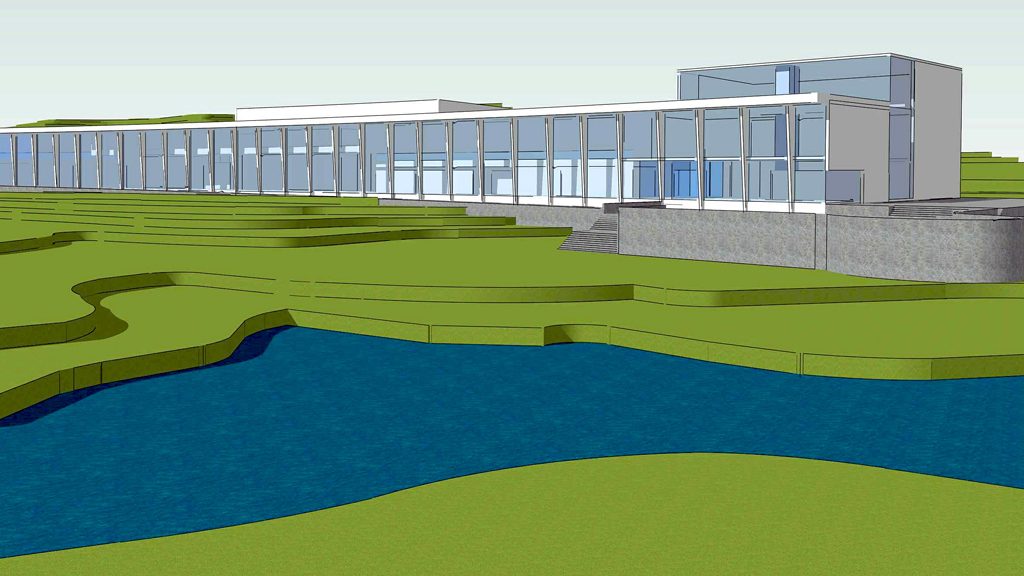

MYM says the project will make it the cannabis capital of Canada. The City of Weedon has bought 329 acres of land for MYM and besides the massive production facility, there will be a cannabis research and testing facility, a museum, an auditorium for lectures and a health care clinic with 22, 1,000-square-foot apartments to accommodate patients getting treatment.

The firm said Houweling brings expertise designing large-scale agricultural production, notably of tomatoes but also more recently of cannabis, and he has worked on a cannabis project of similar size in Australia. He will assemble a team from among his worldwide contacts, including designers and builders Kubo of the Netherlands and irrigation specialists Green Meteor.

The form of the greenhouses will be determined by the growing plan he will create, he said. The plan will emphasize efficiency of labour and production processes to ensure the quality of the product.

“When you start in the design phase, you think about production, what comes in one side and goes out the other side,” Houweling said. “What is critical in the success is how the production flows and how to minimize the potential pest and disease issues. So you design different zones. In this case they will be pressurized to eliminate the possibility of transferring disease or pests from one zone or another.”

His business, Houweling said, is all about avoiding crop failure.

“I really don’t have to tell you how important it is to ensure you’ve got product coming out of there that is top notch and you don’t have failures,” he said.

Once the greenhouses are completed by the fall of 2019, Houweling said, the first crop could be ready for harvesting by that Christmas. With each crop taking eight weeks to grow, there could be six harvests per year. The Weedon facility is targeted to produce annual sales of $1.275 billion with profit estimates of $650 million per year.

His design efforts this year will involve integrating the systems of specialists he knows in design, manufacturing, heating and irrigation from around the globe.

“That is the key, how do you put all design parameters and put the specialists in their own area together and come up with an excellent product and well-designed production facility and well built,” said Houweling.

With some components, such as the complex underground systems, there will be tried and true strategies from his past combined with new systems purpose-built for this project, said Houweling.

“I think the ability to execute comes from having a lot of experience having done it before,” he explained. “Not the same as this but working with people, having a trusted relationship and knowing when you put a plan together it is going to be executed. There are years and years of relationships.”

Leslie will be tasked with ensuring the facility reaches LEED certification. Houweling said elements that will contribute towards the goal include efficiencies in production including motors and lighting, and there will be a geothermal energy system, rainwater recovery and Quebec generates non-GHG-emitting hydroelectricity.

Underground infrastructure will include the heating system, irrigation, CO2 distribution, electrical and rainwater distribution.

Houweling feels this collaborative effort should go a long way towards establishing a new benchmark in large-scale cannabis production — but production will still continue to evolve.

“My gut feeling is, five years from now it is going to be surprising what this industry is going to look like and what the final best practices are going to turn out to be,” he said.

Recent Comments