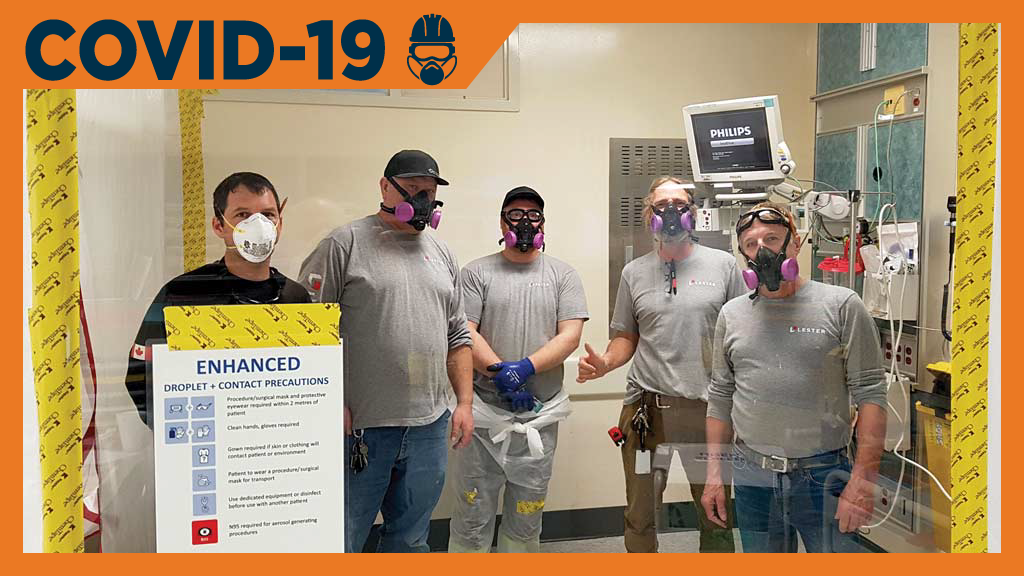

When the Lester Group’s construction foreman Jerry Arnold told his carpentry crew they would be building and maintaining a field hospital for COVID-19 patients, he was surprised by their enthusiasm for a job that could possibly expose them to the virus.

“I was saying, ‘Hey, guys, we have to go into a COVID room — rock, paper, scissors, anyone? By the time I was finished telling them about it, two of them were already in the room,” he recalls.

Arnold is referring to the 100-bed field hospital set up in the St. Clair College SportsPlex for the Windsor Regional Hospital (WRH) in Windsor, Ont.

The project commenced in March with the installation of barriers and other infection control measures around the facility before the construction crew installed 10-by-10-foot cubicles for each patient.

Patient rooms are comprised of a 2.5-inch light gauge steel stud frame covered with walls of heavy-gauge, fire-rated rolled plastic, typically used for infection control hoarding, says Arnold. Wall joints are sealed with infection control duct tape.

The crew also assembled nursing stations and other associated services, he says, adding when the sportplex’s bright lights were bothering some of the patients he devised a ceiling for each room by fastening fabric to a stud secured across the top of the stud wall frame.

Lester Group’s president Bill Lester says the hospital had reviewed several companies’ designs for the field hospital cubicles before selecting the Lester Group in part because it offered a customized design on the fly and was cost-efficient.

It took only two weeks from the design commencement to ushering in the first patients, he says.

The carpentry crew organized an assembly line to make the wall system on a floor and then stand it in place.

Lester says it cost about a third of the price of most of the alternative systems the hospital had been evaluating and, unlike other systems, it could be customized to meet the hospital’s needs.

The carpenters even added some window details in each room and fixed pictures to the walls with tape to increase patient comfort.

Arnold, who has been with Lester for about 15 years, says the contractor leaned on its experience working in WRH in an infection, prevention and control capacity. It has installed barriers and taken other measures for infection prevention at the WRH’s emergency and ICU departments.

Other work the contractor has done recently includes a portable morgue for the WRH assembled in a 40-foot steel shipping container. Structural steel tubing fabricated by Windsor-based Vollmer comprises the racking assembly and a high-density plastic is used for shelving. A plywood subfloor with a cleanable surface and insulation was also installed by the contractor, says Lester.

The carpenters had to co-ordinate the job with ironwork fabricators to ensure the materials were designed and sized properly. Vollmer did the morgue’s mechanical/electrical.

Lester also designed and built a 40-bed field hospital for the Chatham Kent Health Alliance. Taking lessons from the WRH contract, the carpentry crew needed only four days to complete the assembly.

Lester says each of the three jobs used different crews from Windsor’s Carpenters Local 494.

“On each of these jobs the person running the crew was capable of dealing with a broad description of what needed to be done and then made it work,” says Lester’s president.

While the projects were not straightforward and there were health risks for the carpentry crews, most didn’t hesitate to take on the jobs.

“We’re carpenters, this is what we do. We’re helping the city and people were so thankful to us for doing it,” says Arnold.

Recent Comments

comments for this post are closed