The 3.5-kilometre melange of pipes under Windsor, Ont’s oldest neighbourhood is about to get renewed in a non-invasive way.

Capital Sewer Services Inc. of Vaughan has been hired by the City of Windsor to rehabilitate pipe, some of which goes back a century, in a way that doesn’t disrupt traffic on busy Sandwich Street, which leads into the city’s west end from downriver communities and suburban neighbourhoods.

The technology is known as cured-in-place pipe lining and it’s a go-to method for restoring municipal sewers and watermains for a variety of reasons, not least to allow the continual free flow of street traffic above ground.

“That’s the beauty of this type of technology because it allows you a lot more options to work around high-profile, high traffic situations,” Capital’s COO Brian Ratchford says.

Why is that? Simply because there is no need to dig trenches down the middle of a busy street.

There are other advantages too. Less work crew is needed because the main infiltration sites are manholes not open street cavities. Crews can be distributed over a longer area, lessening large – and equally disruptive – concentrations of equipment and workers.

The cured-in-place technique is also faster, with a segment of installation taking four or five hours versus four or five days using conventional open trench installation, says Ratchford.

And, for cities like Windsor that track “climate change mitigation,” this non-invasive approach helps reduce the city’s carbon footprint.

Finally, in many cases the technology is more economical that traditional surface excavation and installation.

“Most of the time it is less expensive than traditional open cut,” Ratchford says.

The $8.5 million Windsor project runs through the city’s historic Sandwich Towne neighbourhood that will also soon also be undergoing $12 million in major renewed streetscaping, part of the “community improvements” committed by the Crown corporation Windsor Detroit Bridge Authority (WDBA) for districts near both the Windsor and Detroit sides of the new Gordie Howe International Bridge, currently under construction.

“I’m pleased that we’ll be able to complete this work with minimal disruptions for residents and commuters, while laying the groundwork for future improvements,” local City Councillor Fabio Costante says.

Capital Sewer, which has worked with municipalities throughout Ontario, uses Wisconsin-based National Liner’s Cured-in-Place-Pipe (CIPP) technology.

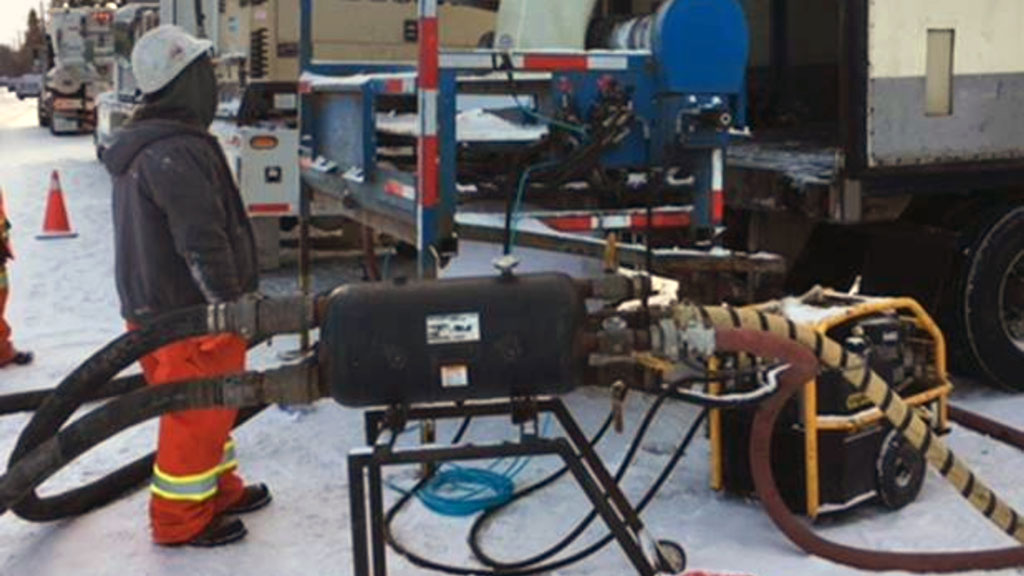

But before installation the old sanitary and combined water pipes, many of which are made of clay, clay tile, brick and concrete and vary in diameter from 200 millimetres to 1,050 millimetres, have to be extensively cleaned. Following CCTV inspection, high pressure water and a hydraulic robot are used to rid pipes of sediment, tree roots and hardened calcite deposits. Crews then pull the debris out through existing street manholes.

For the new lining, some minor excavation will likely be necessary, usually to replace part of a pipe so deteriorated or filled with debris it cannot otherwise be cleaned or repaired.

After the old pipes are cleaned, planning for the installation of the new pipe liner begins. Scheduled installation will be done in sections, essentially taking about half a day, while local water service is temporarily turned off. Each section typically will run from manhole to manhole.

“For a lot of people who might be at work or are away for the morning or afternoon a lot of the time that work will be completed by the time they arrive back home,” Ratchford says.

But the key to this non-invasive rehab is the cured-in-place liner technology itself and the way it is installed within the existing old pipe to create brand-new pipe.

The liner consists of two components, a polyester felt liner and thermosetting resin that saturates the liner during the manufacturing process. This liner can be custom manufactured to different size pipes.

Much of the liner will be manufactured at Capital’s Vaughan plant, cut into segments and transported in temperature-controlled trucks to avoid curing down to Windsor. There will also be a smaller onsite mobile liner production plant for the laterals that will connect to individual businesses and homes along the main pipe route.

“Our intent is to try and have enough liner prepared so it makes good economy and good sense to fill a truck to bring it down. We’re hoping to perform multiple installations once the truck is on site,” Ratchford says.

Once the old pipe has been cleaned and is ready for relining, the resin-infused polyester liner is inserted into the old pipe and expanded using a hydrostatic head of water to press it into place. The resin is thereby forced into cracks and joints of the old pipe walls. Finally, the water is heated allowing the resin to cure, binding with the old pipe and creating essentially the brand-new pipe, with a lifespan of 50 years. The lateral connections are then reinstalled using a remote-controlled cutting tool.

Because this is the oldest neighbourhood in Windsor, a home to myriad artifacts from the area’s Indigenous history as well as early French and British settlement, an archeologist will be on standby.

“If we come across an artifact then everything basically stops,” Ratchford said.

The archeologist will inspect the area, remove the items and give the “green light” to continue, he said.

Recent Comments

comments for this post are closed