A new document released by the Ontario Society of Professional Engineers (OSPE) summarizes best management practices (BMPs) for rehabilitating aggregate pits and quarries in Ontario by backfilling with excess soil.

“This project is important because in Ontario we know that we are producing around 25 million cubic metres of soil every year,” said Dr. Madeh Piryonesi, one of the authors of the report, Best Management Practices for Aggregate Pit and Quarry Rehabilitation in Ontario, presented in a recent webinar.

“This excess soil used to sometimes go to waste or be dumped in landfills. Starting in 2025 that won’t be allowed anymore and contractors and project leaders they must think of ways of beneficially reusing the volumes of excess soil. Pits and quarries are a very good destination for soil to be reused. We have over 5,000 pits and quarries in Ontario that are active at the moment.”

In 2019, the Ontario Ministry of the Environment, Conservation and Parks (MECP) released On-Site and Excess Soil Management Regulation O. Reg. 406/19 but the documents were not developed with specific considerations for pit and quarry settings.

“Our main question was really can we use the standards that are developed by the MECP to develop a safe and flexible set of standards for rehabilitation of pits and quarries using backfill,” said Piryonesi. “This project is important because if we get to develop this set of flexible standards we will be able to rehabilitate more pits and quarries. This means minimizing the safety risks.”

Less truck traffic on the roads is also an added benefit, explained Piryonesi, which translates into “less greenhouse gas emissions, less congestion and less road deterioration. Some of these sites are going to be recreating and repairing wildlife habitats.”

Document features scientific data and BMPs

The document, which includes a scientific review paper as well as BMPs, is intended to complement existing regulations and standards and does not supersede any provincial regulation, municipal bylaws or the Aggregate Resources Act (ARA).

It was developed by the staff and members of the OSPE, with the help of the OSPE Excess Soil Project Steering Committee, made up of industry experts and was funded by the MECP. In addition to Piryonesi, the report was prepared by David Carnegie, a professional engineer and Lee Weissling, PhD.

Through the scientific review, it was concluded that many elements of the MECP generic conceptual site model are applicable to pits and quarries.

Some of the differences between the OSPE paper and the other MECP excess soil documents are it focuses specifically on pits and quarries; MECP generic standards described in O. Reg. 406/19 and the Beneficial Reuse Assessment Tool (BRAT) are considered; microbiological contaminants are discussed; and groundwater-related concerns are addressed, including potential physical and chemical impacts associated with large volumes.

The BMPs, which can be applied to the rehabilitation of licensed and unlicensed aggregate sites, are intended to assist Qualified Persons (QPs), municipalities, aggregate licensees, and operators in evaluating options for using excess soils.

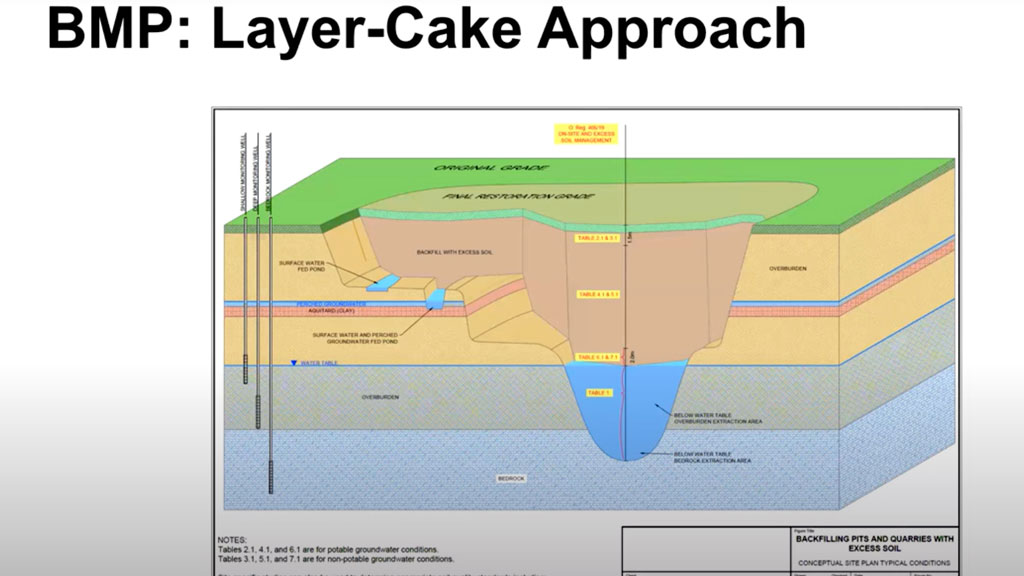

The ‘layer-cake approach’ to site rehabilitation

The BMPs recommend a layer-cake approach to site rehabilitation when considering placement of excess soil, which means different quality of soil and table standards can be placed at different depths as long as certain conditions are satisfied and it also depends on the site itself, explained Carnegie. The quality of the soil appropriate for each layer is shown in a figure in the report.

“At the end what we came up with is this flow chart that is very convenient to use,” Piryonesi explained. “This flow chart is going to be what a practitioner, QP would be using, along with this illustration of this which is what we call the ‘layer-cake’ approach. Essentially, it’s saying we recognize that a pit or quarry can be using a lot of excess soil therefore we are not limiting the QP or operator, the project leader to one table or two tables they could be using multiple tables.”

The BMPs also include potential adverse impacts at pits and quarries that are not specifically addressed by the current regulation.

“This includes microbiological contaminants, invasive species, impact on the physical flow of groundwater flow, noise and dust that can be caused by truck works, erosion of soil and climate change,” said Piryonesi.

Climate change mitigation and adaptation considerations are also addressed by the BMPs.

“The goal of O. Reg 406/19 was to become more climate positive, to have the opportunity of reducing greenhouse gas emissions and rehabilitating pits and quarries can provide this opportunity because of the nature of these sites,” Piryonesi noted. “They are usually close to urban centres and they can contribute to mitigation of climate change if this is done properly.”

For more on the report click here.

Follow the author on Twitter @DCN_Angela.

Recent Comments