TORONTO — A repurposed church, a “sculptural” GO transit station and a challenging Muskoka resort project were just some of the winners taking top honours as 2021 Ontario Concrete Award recipients, Concrete Ontario announced recently.

The awards honour leaders in the concrete industry and recognize the most outstanding projects in the province.

The winners are as follows:

Specialty Construction Methods

Winner: Muskoka Bay Resort, Gravenhurst, Ont.

In total, about 13.4 million pounds of concrete were used to create the floor and wall slabs of the Muskoka Bay Resort, resulting in 381 pieces. The building’s panels totalled 111,928 square feet, with 51,769 square feet for the walls and 60,159 square feet for the floors.

Due to the size of the project, the contractor had to adjust some elements of their normal construction processes since a typical tilt wall build involves installing panels that are the full height of the entire structure. However, in this case, that would’ve meant pouring and erecting panels that were nearly 87’ tall which wasn’t practical. To overcome this, the team took a different approach. Wall panels were designed one floor height at a time, with the floor slabs also being designed as site-cast panels.

Project team: Muskoka Bay Resort (owner); Blackwell Structural Engineers (engineer of record); Trevor McIvor Architect Inc. (architect of record); Alliance Development Corp. (general contractor); Lafarge Canada Inc. (material supplier); Tilt Wall Ontario (tilt wall contractor); and additional participants AGF Rebar Ltd. and Master Builder Solutions.

Architectural Merit — Cast-in-Place

Winner: Tommy Thompson Park Pavilion, Toronto

Tommy Thompson Park evolved with Toronto’s growing downtown metropolis as part of the Leslie Street Spit, which was created by 20 years of lakefill with post-construction and demolition materials, including concrete, rebar, sandstone and brick cast at Evergreen Brick Works. This continuous lake filling allowed the park to grow to more than 250 hectares in size and stretch over five kilometres into Lake Ontario, mutating from a post-industrial wasteland into a natural oasis.

Project team: City of Toronto (owner); DTAH Architects Limited (architect of record); Faet Lab (engineer of record); Somerville Construction, Consulting & Project Management (general contractor); Alliance Site Construction Ltd. (forming contractor); Dufferin Concrete – A CRH Company (material supplier); and additional participants Euclid Canada.

Architectural Merit — Precast

Winner: South Hill Condominiums, Guelph, Ont.

South Hill is a uniquely shaped building with multiple design features from top to bottom. The mid-rise condominium is eight storeys tall with one storey of underground parking. Total precast was the choice for this project to accommodate the limited site access and achieve multiple finishes requested by the client. Large overhang canopies are supported with outrigger precast walls, but hidden with the choice of colour coating. The exterior wall panels are all varying shape and sizes with multiple form liner and multi tonal stain finishes on each piece.

Project team: Thomasfield Homes Ltd. (owner); ABA Architects Inc. (architect of record); MTE Consultants Inc. (engineer of record); Tambro Construction Ltd. (general contractor); Rizz Engineering Inc. (precast engineer); Stubbe’s Precast (precast supplier); and additional participants Sika Canada Inc.

Architectural Hardscape

Winner: Aitken Park, Toronto

Aitken Place Park is a new mixed-use park. UCC Group provided an architectural sandblasted finish along a very distinct serpentine shaped path that flows downhill offering views of Lake Ontario. The sandblast finish provides increased longevity and durability and is effective for anti-slip measures. UCC Group also provided architectural concrete seating and seat wall features.

Project team: Waterfront Toronto (owner); FORREC (architect of record); Arup Group (engineer of record); UCC Group Inc. (general contractor); Dufferin Concrete – A CRH Company (material supplier); and additional participant Euclid Canada.

Infrastructure

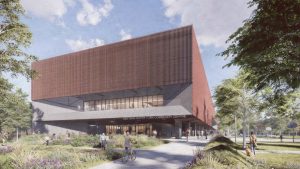

Winner: Bloomington GO Station, Richmond Hill, Ont.

The new GO Station at Bloomington Side Road and Highway 404 is positioned to be a vital transit hub in York Region. The sculptural building serves as a landmark promoting commuter rail through contemporary design and construction. With the prominent use of concrete products in various forms and finishes, the facility design delivers both esthetic appeal and enhanced durability.

Project team: Metrolinx (owner); IBI Group Architects (Canada) Inc. (architect of record); IBI Group Architects (Canada) Inc. (engineer of record); Kenaidan Contracting Ltd. (general contractor); Miller Concrete (material supplier) and additional participants Alumna Systems Inc., EFCO Canada Co., Euclid Canada, Gilbert Steel Ltd. and Master Builders Solutions.

Material Development and Innovation

Winner: Lock 23, 24 and 25, Trent-Severn Waterway, Ont.

Since late 2018, Dufferin Concrete and Dufferin Aggregates have been providing aggregates and concrete for reconstruction work on three dams along the Trent-Severn Waterway. Having reached the end of their lifespan, a repair program was initiated by Parks Canada to have the Douro Dam (Lock 24), the Otonabee Dam (Lock 23) and the Sawers Creek Dam (Lock 25) repaired, with work being led by long-time CRH client EBC Inc. The new dam structures under construction will have a lifespan of over 60 years and will contribute to reducing leakage and increasing the safety of water management operators and the public.

Project team: Parks Canada (owner); SNC Lavalin (engineer of record); Maple CDB JV (general contractor); EBC Inc. (concrete contractor); Dufferin Concrete – A CRH Company (material supplier); and additional participants Euclid Canada AGF Rebar Inc.

Mid to High Rise Residential — Cast-in-Place

Winner: Marche St. Charles Market, Ottawa

The repurposed church will be transformed into a restaurant and local marketplace, where its grounds will once again serve its neighbours with seasonal attractions. The new condos and townhomes will wrap around the church to create a European-style marketplace with cafés and restaurants, as well as outside public spaces and gardens.

Poured concrete was used for the structure of levels one through six. Levels seven and eight are a mixture of steel with concrete floors.

Project team: ModBox Inc. (owner); Linebox Studios (architect of record); Cleland Jardine Engineering Ltd. (engineer of record); The Lake Partnership Inc. (general contractor); Tomlinson Ready Mix (material supplier); and additional participants Master Builders Solutions.

Mid to High Rise Residential — Precast

Winner: Circa 1877 Condominiums, Waterloo, Ont.

Circa 1877 is an eye-catching mix of historic and modern architecture. Previously home to one of Canada’s first craft brewers from 1984 to 2015, a piece of this heritage building remains to stand proud in Waterloo. A total of 20 storeys with six parking levels, 14 residential levels and one mechanical penthouse level was erected by Stubbe’s Precast’s installation crew. The project included 4,100 precast pieces total.

Project team: HIP Developments Inc. (owner); ABA Architects Inc. (architect of record); MTE Consultants (engineer of record); Melloul-Blamey Construction Inc. (general contractor); Rizz Engineering Inc. (precast engineer); Stubbe’s Precast (precast supplier); and additional participants Sika Canada Inc.

Specialty Concrete Applications

Winner: ECOPACT Concrete

ECOPact concrete meets CSA and ASTM standard specifications for all concrete and can be tailored to meet specific project requirements. Lafarge’s ECOPact concrete is an engineered low carbon concrete utilizing higher blends of cements using cementitious substitutes along with ECOPlanet cement, that ranges from 30 to 100 per cent CO2 reduction compared to a standard Ordinary Portland Cement (OPC) mix.

Project team: Lafarge Canada Inc., Innocon Inc. and Allmix Concrete Inc. (material suppliers).

Sustainable Concrete Construction

Winner: Putman Family YWCA, Hamilton, Ont.

Coreslab Structures provided a total precast solution for the YWCA project allowing the building to achieve Passive House certification. The total precast structure incorporated a load bearing wall, continuous insulation, airtightness and an exterior finish all in one component. The building consisted of over 330 precast components, including wall panels, beams and columns and over 43,400 square feet of precast hollow core slabs.

Project team: YWCA Hamilton (owner); Kearns Mancini Architects Inc. (architect of record); RJC Engineers (engineer of record); Schilthuis Construction Inc. (general contractor); Coreslab Structures (ONT) Inc. (material supplier); and additional participants Sika Canada Inc.

Recent Comments

comments for this post are closed