Can buildings be practically constructed using materials that store carbon, rather than release the global warming chemical element into the atmosphere?

Chris Magwood, director for Builders for Climate Action and manager of carbon-free buildings at RMI, thinks so. But it will require a paradigm shift in the approach to how we design and construct buildings.

Magwood’s lowrise residential/commercial design and construction experience illustrates the value of biomass materials or “grown products” that act as carbon traps such as hemp, straw, cork and even mycelium (mushroom roots) compressed into panels for insulation.

Trent University’s new forensics facility Endeavour Centre, a not-for-profit sustainable building school in Peterborough, Ont., selected a number of biomass materials to help the design team reduce the carbon footprint of the original building plan by more than 85 per cent. Those materials include precast hemp-crete blocks and hemp batt and wood fibre insulation.

“This is an example of real building built affordably and an incredibly low carbon building or even a carbon storing building.”

Magwood, who presented a webinar on carbon trap building materials recently at the Wood Solutions Conference hosted by the Canadian Wood Council, says buildings use roughly 40 per cent of all the materials harvested on the planet.

“If we can turn a lot of that mass and biomass into other means of carbon storage then we can get to 100 per cent reduction” of carbon emissions.

Designing and constructing buildings with regional biomass materials for 25 years, Magwood has been involved in a number of studies on the carbon footprint of materials in lowrise buildings, including one for Natural Resources Canada on 190 model homes and another on as-built homes in the cities of Nelson and Castlegar, B.C.

He is about to release the findings of research on 500 as-built homes in the Greater Toronto and Hamilton Area.

From the data compiled for those studies, he says carbon emissions from new housing represents a carbon emissions number that is about double what is should be by 2030 if Canada is to meet global warming climate targets.

Among the 700 total homes he has studied, Magwood says those with “a lot of biomass materials” such as mass timber and other organic materials fared better for carbon storage.

“The designs or the sizes of the homes weren’t particularly different…there were no big factors other than the use of biomass materials.”

But Magwood says the current way that life cycle assessments (LCA) tabulate carbon emissions is “completely inadequate” and “misleading” at evaluating biogenic carbon storage.

LCA’s typically represent biogenic products “only fractionally better” than conventional materials because “they show a lot of carbon coming out at the end” of a biomass material’s life.

In the real world, however, the climate impact of biomass or biogenic materials from the point of harvest to end of life is often negligible.

By comparison, initial CO2 emissions from conventional materials are substantial and continue for 100 years.

Armed with that understanding, he says there are growing legions of people who believe carbon storage in buildings “could actually help transform the entire climate crisis.”

There are hurdles, however. For one, the forestry industry must address issues around wood (think mass timber) as part of the solution to global warming through carbon storage.

Magwood says during logging operations, carbon is released into the atmosphere when trees are felled and also through the disruption of soil.

There are other concerns at point of harvest as well.

“This isn’t to say that forest products can’t be valuable biomass for carbon storage in buildings but what it is saying is that there is enough uncertainty now. We’d like to see the (forestry) industry address some of the larger concerns.”

Wood will have lower emissions than concrete or steel in the same design but it might not deposit “meaningful storage” to make a difference in the climate change formula.

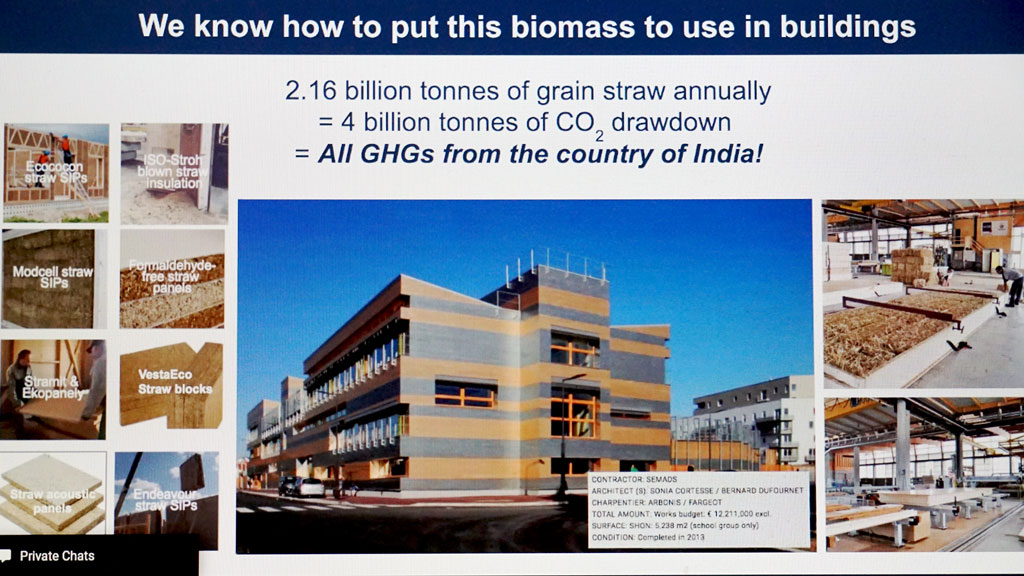

Alternative biomass materials such as straw from harvested grain have proven to be effective carbon sinks in the form of blown-in insulation, compressed insulation and acoustic block panels.

“These grown products” represent “the potential for billions of tons of net storage.”

Recent Comments