A $62.9 million bridge project in Victoria B.C. is anticipating a 10-month delay due to issues with steel fabricated in China.

According to recent reports drafted by the city’s engineering and public works department, a quality control consultant overseeing the steel fabrication in July found that some aspects weren’t done in accordance with the Johnson Street Bridge’s design specifications.

"The project team is working to get the fabrication restarted and a meeting is scheduled at the plant in China in February to finalize procedures and resume fabrication," read the report.

The firm selected by the general contractor, PCL, for fabricating the bascule leaf is ZTSS Bridge located northwest of Shanghai in China.

MMM Group is providing engineering services on the project.

The steel elements to be fabricated include the rings, north and south trusses and the orthotropic deck.

One of the two rings is being replaced while the other is being repaired.

The north truss steel will be replaced.

New steel has been ordered.

Fabrication is tentatively going to recommence in March, pushing the project completion date back 10 months.

According to the report, staff will continue to maintain the existing bridge, built in 1924, until the new one is operational.

The delay could also affect costs.

According to the report, roughly $1 million had been allotted for contingency until the end of December.

However, additional steel consulting costs to resolve the china issue, along with habitat compensation, legal costs, soil work and other expenses are burning through the contingency fund.

The project director and engineers asked city council to increase the funding.

City councillor Ben Insitt said he’s had concerns about the project’s scope and unconventional design from the beginning.

"Now I think my concerns are bearing fruit," he said.

He said that rather than go with a simpler project, like refurbishing the old bridge, the city decided to develop a new iconic structure.

This is something Insitt believes the city doesn’t have the tax base to support.

The new bridge will be the largest single-leaf bascule bridge in Canada – and one of the largest in the world.

He also criticized the project’s complex procurement, involving two major companies – PCL and MMM Group.

There has been a two year delay in getting the final design, prompting all parties to point fingers at who should pay for significant cost escalations.

"It was a mistake to decide that it had to be iconic," Insitt said.

The parties are currently in mediation with each other and the city to resolve the payment disputes.

According to Tareq Ali, communications director for The Canadian Institute of Steel Construction (CISC-ICCA), picking offshore fabricators for steel seems like a good decision, but ends up costing more in the long run.

The institute’s case studies show that initially quotes from offshore steel suppliers end up being 30 per cent less than Canadian quotes.

But then it looked at "total installed cost" or the cost incurred at the final completion of the project.

After possible delays, assembly and quality issues, Canadian steel ends up being 12 per cent cheaper.

Despite the setbacks, the report shows significant progress has been made.

Items on the west side, including realignment of approaches and landscaping, are ahead of schedule.

Various roads near the approaches are beginning to open, giving contractors more room to work.

Completion of the bridge’s concrete foundations is scheduled to finish early this year.

Work is also being done to prepare for the bascule pier for a massive concrete pour.

The pour will use about 1200 cubic metres, or 120 truckloads, of concrete.

It will be the biggest single concrete pour in recent Victoria history.

Specialized cooling hose coiled throughout the concrete will assist in controlling the rate of cooling in the same way a radiator controls an engine’s temperature.

1/3

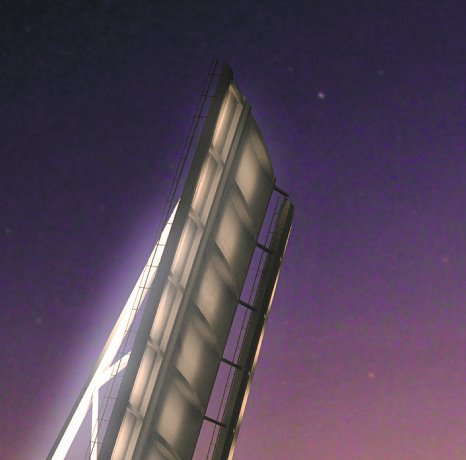

Construction of a new Johnson Street Bridge to replace a structure built in 1924 will be delayed by about 10 months.

Photo: City of Victoria

2/3

Recent Comments

comments for this post are closed