A partnership between a Vancouver Island First Nation and a Vancouver company focused on lithium battery assembly is touting itself as Canada’s first Indigenous-led gigafactory.

A gigafactory is a large-scale manufacturing facility where electric batteries are produced and/or assembled on a grand scale.

“We were looking for a long-term partnership with an understanding of our vision of renewable technology,” says Broderick Gunning, CEO and president of Energy Plug, whose business is assembling lithium iron phosphate battery packs for residential and commercial storage uses.

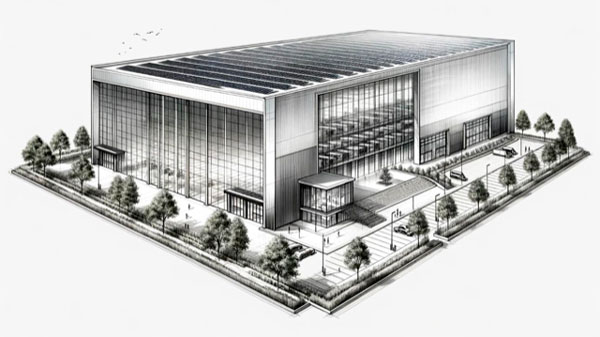

Energy Plug wants to enter into a long-term partnership with the Malahat First Nation. Plans are to build a 100,000-square-foot battery assembly and research facility at the nation’s Malahat Business Park, a 52-acre industrial park in Mill Bay, roughly 40 killometres north of Victoria and fronting the Trans-Canada Highway.

The Malahat First Nation, with 51 per cent ownership, would be responsible for building the facility, while Energy Plug would provide leadership, sales, partnerships and finance creation of the internal systems, which include offices, engineering, robotics, research and development.

The Malahat First Nation’s director of economic development notes negotiations haven’t concluded for the project.

“We’re focused on land, utilities and a long-term partnership,” says Tristan Gale, who started work with the nation as a fisheries biologist almost eight years ago.

Discussions to finalize planning and engineering need to happen, he says.

Gunning, who remains excited about the joint venture, says Energy Plug spent much of 2023 searching throughout Canada for a suitable partner.

“The Malahat checked all the boxes,” he says.

Those boxes include sitting at tidewater, access to electricity and being located in a free trade zone, a location where goods can be shipped, handled, manufactured, reconfigured and re-exported without involvement of customs agencies.

Gale points out with 11 kilometres of waterfront, the Malahat First Nation is in charge of one of the few deep-sea ports on the West Coast that isn’t booked up.

As well, the Malahat First Nation is a Land Code Nation, which means the nation is in control of zoning, permitting and taxation on its lands.

Also driving the project is that locally the Malahat Nation, amongst others, will eventually exceed the amount of electricity available. By having a majority stake in the battery facility, the nation will be able to both build and use the battery storage systems, Gale says.

And after more than 25 years of negotiations, the Malahat Nation is close to finalizing the transfer to it of an estimated 3,000 acres of land, which will add to its energy needs. Having the electricity for both new lands and industry, and for existing band members, roughly 370 today, is important for future development, Gale says.

Once built, the factory will also be used for research on lithium, nickel, manganese, cobalt, sodium-ion and solid state batteries.

The assembly will be done with battery cells that arrive from Asian countries like China and Korea. The cells will be assembled into five to 100 kilowatt packs, Gunning says.

“They’re not electric vehicle packs,” he notes.

The batteries are for storage so that users have a backup system for the grid.

Building plans entail a two-storey, solar-powered facility with offices and labs on both or on a mezzanine level.

There will also be three to five fully-automated (robotics) assembly lines, Gunning says.

The number of employees remains undetermined.

It’s also uncertain whether the factory will be built in one or two stages, Gunning says. If in two rounds, the first will be 30,000 to 50,000 square feet and the second another 50,000 square feet of space.

The cost of the facility remains unfixed.

And while engineering studies have been done, a contractor for the project hasn’t been secured, Gunning says.

A formal groundbreaking is planned for early February, Gunning forecasts.

He expects the plant to open the in the second quarter of 2025.

Recent Comments