PCL Construction, RJC Engineers, B+H Architects and Walters Group joined forces earlier this month to contribute to Let’s Make History Again, a fundraiser in support of the Juvenile Diabetes Research Foundation (JDRF).

The event featured the Flagpole 100 challenge, which was inspired by Oliver & Bonacini restaurant co-founder Peter Oliver who 32 years ago lived on top of a flagpole until he raised $250,000 for diabetes research after his six-year-old daughter was diagnosed with type one diabetes (T1D).

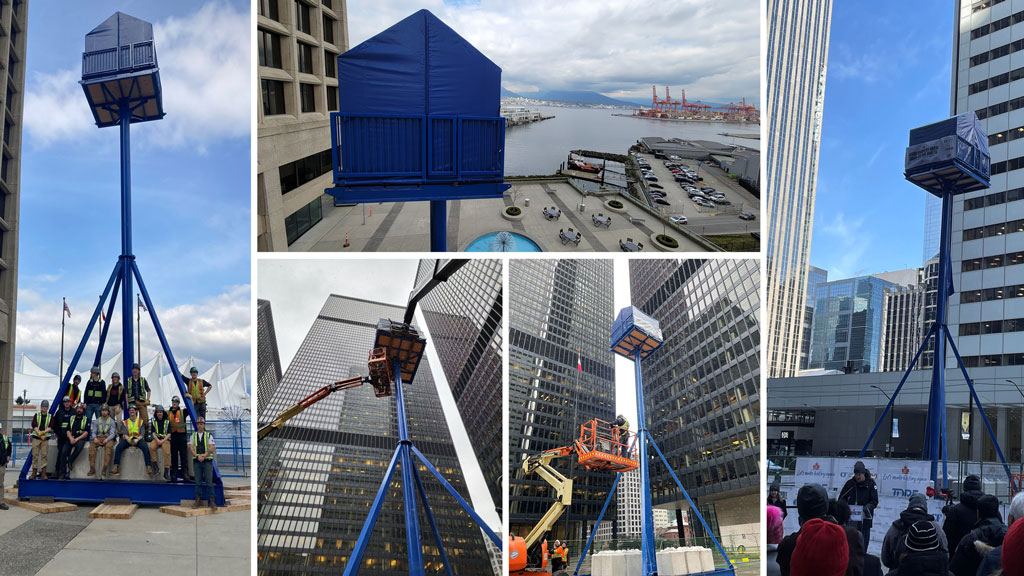

For this year’s challenge, individuals camped out for 100 hours in enclosed structures on top of 40-foot flagpoles in Montreal, Toronto, Calgary and Vancouver to raise funds to help find a cure for T1D. The fundraiser was part of the JDRF’s larger $100M Campaign to Accelerate.

The event marks the anniversaries of the discovery of insulin and the first successful injection of insulin both of which took place in Toronto 100 years ago.

For Mike Jackson, construction manager at PCL Construction, the cause hits close to home. He has two children with T1D. Although there is no history of diabetes in the family, both children were diagnosed at the age of seven.

“They really don’t know a life without diabetes,” Jackson explained. “For them every single meal that they eat, every candy that they have, every snack, it’s all tracked and monitored…You don’t get time off from diabetes.”

Jackson said he is thankful PCL supports the cause.

“When they do something like this that’s really near and dear to my heart, where they are supporting something that impacts my life and my kids’ life on a day to day basis, it hits closer to home…It’s raising awareness within our organization about diabetes and helping push for a cure.”

B+H Architects was engaged to co-ordinate the logistics, design and delivery of the five flagpoles.

The sites were made available by Cadillac Fairview. RJC Engineers was engaged to develop design options.

The flagpoles were fabricated and assembled by Walters Group, with PCL Construction co-ordinating the setup and takedown.

The design, fabrication, delivery, erection and removal of all five flagpoles, along with use of the sites, were donated at no cost to the foundation, indicates a release.

Tibor Kokai, principal emeritus with RJC Engineers, received a call from Daniel McAlister, honorary chair with B+H Architects, who enlisted his help to design the flagpoles.

“They wanted me to fine tune the structure and basically to make it as cost effective as possible,” Kokai told the Daily Commercial News.

“I did two things: number one I looked at what this structure should look like and two, I tried to find a structural steel supplier who would supply this whole thing for free.”

Kokai worked closely with Walters, the structural steel suppliers and installers.

“They said yes to supply and manufacture all these towers for free,” Kokai said.

“I know from how structural steel construction goes, you can design something as a structural engineer but if you co-ordinate that with the structural steel supplier then you can design something they would like to build. It was really teamwork.”

One of the challenges was to establish the stability of the tower. It started with a 15-foot base.

“These towers have no real foundations. They were supposed to be just placed on the surface of the walkway or sidewalk,” said Kokai, adding they consulted with different companies to ensure the structures could withstand winds. “Since these towers have no footings we had to put weight on them so they didn’t flip over…The tower has a base loaded with concrete blocks.”

The flagpole, which weighs 4,500 kilograms, needed to be much sturdier than a regular one.

“The pole was a round steel column a foot in diameter,” said Kokai. “It was designed so it’s stiff enough so it doesn’t move too much and doesn’t create sea sickness for people who are up there.”

On top of the pole there was an eight-by-eight-foot square platform with a railing around it where a tent was placed.

All five flagpole structures were fabricated and painted entirely by volunteers across five of Walters Group plants. Workers volunteered their time on two Saturdays.

“They cut the structural steel to size shown on our drawings, they bolted them together, they painted them, they preassembled them so they could be assembled on the site,” said Kokai.

The flagpoles were located at the Toronto-Dominion Centre; UHN (Toronto General Hospital); 200 Granville St. in Vancouver; Calgary City Centre; and Rio Tinto Indoor Courtyard, 1160 Av. des Canadiens-de-Montréal.

Installation at the TD Tower in Toronto went smoothly but the UHN site on University Avenue presented some challenges.

“Installing around TD Towers was easy because it was right on a nice plaza where everything is horizontal but at UHN on University Avenue we were sitting on sidewalk which was sloping so we had to shim it so it becomes horizontal,” he said. “It was quite a feat.”

Follow the author on Twitter @DCN_Angela.

Recent Comments

comments for this post are closed