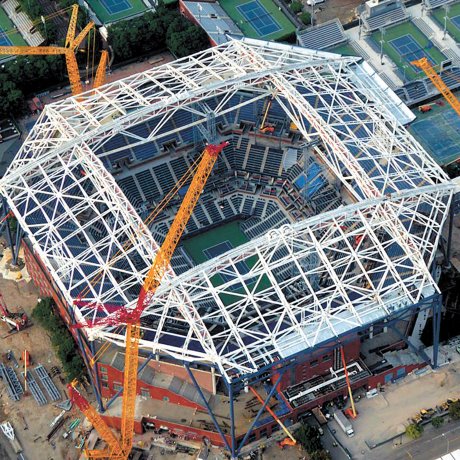

When the 2016 U.S. Tennis Open gets underway in late August, it won’t be impacted by wind or rain thanks to a retractable roof supported by tree-like steel columns.

Touching down on the ground at only eight locations, a new structurally independent 210,000-square-metre PTFE (polytetrafluoroethylene) membrane retractable roof at Arthur Ashe Stadium will allow the Open and other tennis matches to proceed no matter what the weather is like. This U.S. Tennis Association’s stadium is located just outside of New York City.

The eight columns sit on massive concrete bases, each of which is supported by 20 piles because of the swamp-like soil conditions underneath the stadium, according to information posted on the website for Birdair, the roofing contractor.

At each of those eight locations, two cast steel connections at the ends of the diagonal brace members connect to the vertical columns.

Weighing about 7,700 pounds each, the castings have been designed to transmit lateral and gravity loads passing from the roof, down through the 38-inch diameter steel braces, into the foundations at the base of the eight columns, says Carlos de Oliveira, a principal with Cast Connex Corporation.

The castings are also very much an architectural element. As the home of the U.S. Open, the stadium is visited by thousands of spectators who will walk right past and view the connections, he said.

Toronto-based Cast Connex wasn’t part of the original project team which includes Rossetti Architects, structural engineer WSP, general contractor Hunt Construction, Birdair, and Canam-Heavy, a division of Canam Group, the steel designers and fabricators.

However, it became involved in the project mid-way through 2014 when the New York City Design Commission asked the tennis association and its consultants to develop more esthetically pleasing brace connections at the column base.

"It (the commission) wanted something more elegant and that wouldn’t have been possible with a more conventional plate system."

That request necessitated a very aggressive and time-compressed redesign by Cast Connex and some production changes by Canam, says de Oliveira.

"We’re the only ones that do what we do," says de Oliveira, in explaining why Cast Connex was given a turnkey contract to design and supply single-piece attractive-looking castings. That was in June of 2014 after the steel contracts were being issued.

Its designers had to work very hard and fast to come up with a new design. The "very last minute" process required a simultaneous review of the castings design by the architect, the structure engineer and Canam.

The actual fabrication was subcontracted to a foundry in the United States. Then the castings had to be transported to Canam’s facilities in Quebec and incorporated into the overall steel fabrication process. By November 2014, the columns, supporting braces and castings had been erected, de Oliveira said.

For Canam, the biggest challenge of the brace redesign was meeting the architect’s esthetic requirement, says Serge Dussault, vice-president of preconstruction.

But the entire project was a massive challenge. The roof consists of a 6,000-ton fixed section and a retractable component comprised of two, 500-ton panels, he noted.

Using its main plant in St. Gédéon, Que., but with additional support provided by ADF in Terrebonne and Supermetal (also in Quebec) and PKM in Kansas, Canam began fabricating and transporting tons of steel to the site. Included in that inventory has been four box trusses composed of 58 spliced sections, eight perimeter trusses, 713 beams and eight mega columns, says Dussalt.

Erection of the fixed section by Derr & Isbell Construction was carried out between the off seasons of the 2014 and 2015 U.S. Tennis Opens (which are held in late August and early September).

"All erection work done from outside of the building was done using cranes."

Erection of the retractable section commenced last October and is scheduled for completion this April, says Dussault.

"We were involved in the construction of the stadium in the late 1990s, so it is an honour to come back and complete the roof."

Recent Comments

comments for this post are closed