The opening of Alberta’s largest geothermal heating and cooling system is drawing a lot of attention.

The opening of Alberta’s largest geothermal heating and cooling system is drawing a lot of attention.

The 65,000-square-foot Alberta Regional Council of Carpenters and Allied Workers building includes a meeting hall, offices and administrative areas, and more than 30,000 square feet of training facilities for scaffolding and carpentry and the province’s first millwright shop.

The facility, which opened last fall, was a case study at this year’s Buildex Edmonton.

Its HVAC system combines a geothermal field with a gas-fired boiler.

The geothermal field provides the building with 70 per cent of its peak and 90 per cent of its seasonal heating, as well as 100 per cent of the peak and seasonal cooling requirements.

Ventilation is performed through heat-recovery ventilators.

Hamish Moir of Earthsource Geothermal was part of a recent panel discussion on the system’s construction.

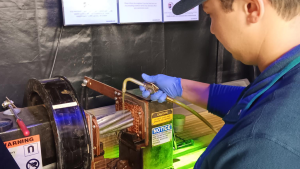

He explained the process of bringing geothermal heat to the building from the 110 vertical boreholes.

“It’s a series of 200-foot deep boreholes – a three and five eighths (inch) diametre hole is drilled and we send a three quarter inch pipe down with a u-tube at the bottom and bring it back up,” he said.

“These are collected typically in groups of ten or so holes together, and then a two-inch header going into the building.”

He explained that the holes are located in small groups because they are easier to deal with and make maintenance easier.

“It’s a lot easier to simply close a valve in one header and you may have lost one tenth of your field capacity,” Moir said, adding with one large header, the entire system is down until a leak is found and repaired,” Moir said.

It was also challenging to co-ordinate the boreholes with other site services.

“There was a real push to get the drilling done before winter season,” he said, adding this meant that the geothermal component was started before site services.

The expert said the large field was built to combat Alberta’s harsh winters, where it can be -40C one week and 10C the next. For the system to handle 100 per cent of the peak heating load, the existing field size would have to be 40 per cent larger.

“We looked at that and we did a cost-benefit analysis and we said ‘you know, for the life cycle of the building, it makes a lot more sense to size the geothermal field for 100 per cent of the air conditioning load’, ” he said.

For temperatures warmer than -20C, the system handles 100 per cent of the heating load with the field alone, but when the thermometer dips below -20C, the gas-fired boiler assists.

However, the boiler does more than augment the geothermal system.

Because the facility combines administrative and training components, the boiler was essential in heating the shops, which need quick pick-up, particularly when large overhead doors are opened in winter.

Moir said in-floor heating is common, but wasn’t an option in the shop areas because changes to operation could involve drilling into the floor in the future.

Recent Comments

comments for this post are closed