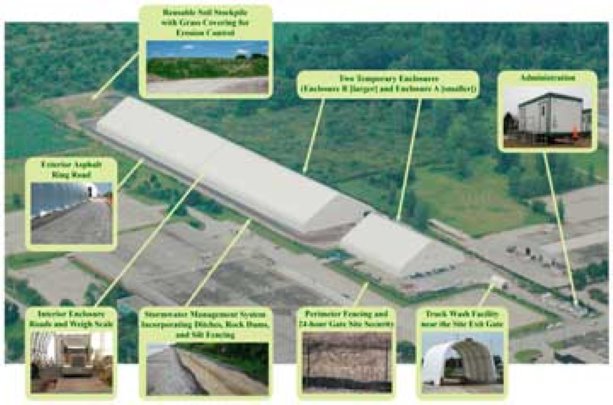

As part of a project ordered by the Ontario Ministry of Environment to clean up PCB-contaminated soil near Pottersburg Creek in London, Quantum Murray LP erected two large temporary steel truss membrane-covered dome enclosures over four vaults to safely contain particulate matter and PCB emissions and to prevent rainwater contact.

For now, the future use of a vacant three-hectare parcel of land in the Pottersburg Creek watershed in London, Ont. hasn’t been determined. But the property once housed the largest PCB storage site in Canada and its remediation may set the standard for similar remediations.

“It was the first site in Canada where an enclosure was built (for a remediation),” says Meggen Janes, client services manager, CH2M Hill, the consulting engineer on the approximately $100-million remediation carried out by Quantum Murrray LP throughout much of 2009 and 2010.

As the site was in an urban setting, the remediation had numerous designs and monitoring components to protect the public and the environment. Just some included a monitoring/early warning system which included offsite air monitors with wireless communication, plus a public/outreach program to keep residents informed.

While those measures are now almost standard, they weren’t as commonplace at the time, suggests Janes.

The roots of the project reach back to the early 1980s when the Ministry of the Environment ordered Westinghouse Canada to build a storage facility after PCBs had been detected in the watershed near its plant. Comprised of four partially-below vaults built with clay/topsoil caps, the facility was later acquired by the ministry to store PCB contaminated soil which had migrated on to adjacent properties and into nearby storm drains, says Janes.

At the time, there was no practical technology for PCB destruction, so the material was securely stored in the vaults and left there for more than two decades. That all changed with the introduction of new technologies and the passing of a federal government regulation that required the removal of in-storage PCB waste to an approved destruction facility before the end of 2009, says Janes.

To comply with that regulation, the Ministry of the Environment launched a massive remediation of the Pottersburg site which got underway that year.

As part of its successful bid for the project, Quantum Murray LP proposed and then erected two large temporary steel truss membrane-covered dome enclosures over the four vaults to safely contain particulate matter and PCB emissions and to prevent rainwater contact. Disposal trucks entered the enclosures, which stretched the length of three football fields, from one end and exited through another.

“It was like a giant assembly line,” says Janes in describing the operation which consisted of anywhere from 20 to 25 trucks on site each day, in addition to the excavation conducted by five pieces of heavy equipment including a loader, bobcats and excavators.

During the first year, almost 104,000 tonnes of waste contained within the vaults and another 2,400 tonnes immediately adjacent were removed and trucked to the Récupère Sol Inc. (RSI) thermal treatment facility in Saint Ambroise, Que.

In 2010, a further 4,900 tonnes outside the vaults were also removed. In total almost 3,100 truckloads of the PCB contained soil were sent to the Quebec facility, says Janes.

Concurrent with the excavation and trucking operation and continuing long after it has been completed was an intensive environmental assessment of the site by CH2M Hill field staff to determine the effectiveness of the remediation. Just some of the activity, carried out with the help of the remediation crews, included drilling 231 boreholes, the creation of 63 test pits and the installation of eight monitoring wells.

Completed in late 2010, the assessment confirmed that the PCBs had been removed, says Janes.

In a way though, the project is still ongoing. A small-scale PCB remediation currently underway of an industrial property in Toronto is using some of the measures first implemented at Pottersburg, she points out.

Recent Comments

comments for this post are closed