TORONTO — LRT stations, a barn, wading pool, science and tech museum and a unique Toronto condo were just some of the winners of the Ontario Concrete Awards, which honour leaders in the concrete industry and recognize the most outstanding projects in the province.

Due to the pandemic, the awards were presented virtually today (Dec. 2) as part of the first-ever Buildings Week. The winners are as follows:

Architectural Merit

Cambium Farms in Caledon — Two new amenity buildings were added to the barn. The team decided to use concrete for the structures of the buildings, a nod to the silos on the property, while using the unique board-form technique to pay homage to the wood-sided barn. All new construction was made to reflect the surrounding concrete outbuildings. The project was completed in spring 2019.

The architect of record is ERA Architects Inc.; the engineer of record is Revive Engineering Inc.; the general contractor is Colin Williams Construction; the concrete contractor is Calibre Concrete Inc.; the material supplier is Dufferin Concrete – A CRH Company; and Euclid Canada was an additional participant.

Architectural Hardscape

Centre Island Wading Pool Conversion in Toronto — A variety of concrete textures and finishes were used across 1,500 square metres using 400 cubic metres of concrete. These finishes can be seen throughout the splash pad with the use of pedestrian and vehicular grade concrete paving, exposed aggregate paving, colour hardeners, sandblasted concrete spray walls, impressed coloured concrete boardwalks as well as visqueen coloured concrete. The project was completed in July 2019.

The owner for the project is the City of Toronto – Parks, Forestry and Recreation; the architect of record and the engineer of record are STUDIO tla (Terraplan); the general contractor is UCC Group Inc; the material supplier is Mobil-One Concrete Limited; and the additional participant is Carpenters’ Union Local 27.

Infrastructure

VIVA Streetscape Redevelopment in Vaughan — The project involved the construction of the transit centre median, concrete walls, curbs, paving as well as reconstruction of the pedestrian boulevard including concrete walkways and curbs all on cupolex soil cells.

The owner is Metrolinx; the architect of record is IBI Group Architects (Canada) Inc.; the engineer of record is WSP; the general contractor is UCC Group Inc.; the material suppliers are Toronto Redi-Mix Limited, St. Marys CBM; and additional participants include Carpenters’ Union Local 27, EDCO Construction, Euclid Canada and Master Builders Solutions.

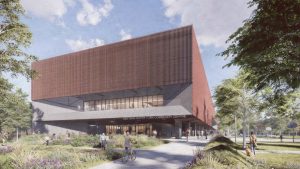

Institutional Building

Ingenium Centre, C3 Building — Science and Tech Museum in Ottawa — The new 36,000-square-metre, cast-in-place concrete building is the size of a football field and while it has only four floors it is the equivalent height of a 10-storey building. The concrete structure incorporates 7.5 metre floor-to-floor heights, and nine to 12.5 metre column spacing was achieved with a cast-in-place concrete flat slab with drop panels, supplemented by cast-in-place concrete beams where required. It was completed in August 2020.

The engineer of record is WSP; the material suppliers are St. Marys CBM and Master Builders Solutions; the architect of record is Diamond and Schmitt Architects Inc. and KWC Architects; and the general contractor is Pomerleau. Additional participants include Carpenters’ Union Local 93, Doublespace Photography and Master Builders Solutions.

Material Development and Innovation

Paradigm Condominiums in Burlington — The highrise residential building is beside the Burlington Go Station and along the railway tracks, so a “crash wall” was incorporated into the design of the overall structure. The wall runs the entire length of the north side of the property line and is required in case of a train derailment. The project was completed in June 2019.

The architect of record is Graziani + Corazza Architects Inc.; the general contractor is Molinaro Group; the forming contractor is Premform Limited and additional participants include Euclid Canada, LIUNA 183 and 187 and Salit Steel Limited.

Mid to High Rise Residential – Cast-In-Place

1 Yorkville Condominium in Toronto — The project is a 58-storey condo with six levels built underground before rising to 183.2 metres in height. In December 2016, the raft slab was completed, which consisted of 2,500 cubic metres of a self-consolidating high performance concrete in one continuous pour. Completion was October 2020.

The owner is BAZIS Plazacorp; the engineer of record is Jablonsky, Ast and Partners; material suppliers are St. Marys CBM, Master Builders Solutions; the architect of record is Rosario Varacalli; the general contractor is TMG Builders; and additional participants include LIUNA Local 183, Master Builders Solutions and Verdi Forming.

Mid to high rise residential – Precast Project

Trent-Durham Residence and Academic Building in Oshawa — The facility is 4,673 square metres of solid precast wall panels, 1,000 square feet of 17-inch thick loadbearing precast sandwich wall panels, 53,800 square feet of hollow core floor slabs, 502 feet of precast columns and precast beams.

The owner is London Property Corporation; the engineer of record is Santarelli Engineering Services; Precast engineer EXP; the material supplier is Stubbe’s Precast; the architect of record is Hanna, Ghobrial and Associates Ltd.; the general contractor is London Property Corporation; and additional participants are Carpenters’ Union Local 397, Marcel Stanford, Outspan Concrete Structures Ltd. and Sika Canada.

Specialty Construction Applications

Dufferin E-Ticketing — Electronic ticketing is the newest of Dufferin Concrete and ORM’s suite of paperless solutions that eliminate lost delivery tickets and ticket storage. Dufferin Concrete partnered with Mike Loconte to pilot the project at Chelsea Maple Residences in Vaughan, Ont., which led to the transition to e-ticketing for the companies in October 2019.

The owner is Saddlebrook Management Consultants Inc.; the general contractor is Chelsea Maple Residences; the material supplier is Dufferin – A CRH Company. Additional participants include Ontario Redimix and Demix Beton.

Specialty Construction Methods

Crosslinx Eglinton LRT — SEM stations in Toronto — Dufferin Concrete came out with a unique shotcrete mix that satisfied all the specifications and construction requirements to withstand summer and winter conditions, with stabilization times that reached a maximum of 18 hours. The product also addressed the sustainability requirements by optimizing concrete mixes to reduce CO emissions. The date of completion was September 2020.

The owner is Metrolinx; the general contractor is Crosslinx Transit Solutions; the material supplier is Dufferin Concrete – A CRH Company. Additional participants are Avenue Group; Carpenters’ Union Local 27; Euclid Canada; Harbles Construction; Ironworkers Local 721; Limen Group; Master Builders Solutions; Outspan Concrete Structures Ltd.; Res 2000 Structures Inc.; Structform – Structural Group of Companies; and Verdi Alliance.

Structural Design Innovation

99 Atlantic Ave. commercial tower in Toronto — The $45 million office building, completed in August 2020, is designed to complement the two existing historical buildings on the site using a classic brick veneer combined with set-back curtainwall panels. The project is targeting LEED Gold certification. The concrete volume on the project is 12,500 cubic metres and maximum concrete thickness is 800 millimetres deep post-tensioned beam at level 2.

The owner is Kevric Real Estate Corporation; the engineer of record is Stephenson Engineering Ltd.; the architect of record is WZMH Architects; the general contractor is SKYGRiD Construction Inc.; and the material supplier is St. Marys CBM. Additional participants include Hardrock Forming Co. Ltd; Salit Steel Limited; BBR Canada; The HIDI Group; Ironworkers Local 721; JSW + Associates; WSP; Vortex Fire; Master Builders Solutions; and Carpenters’ Local 27.

Sustainable Concrete Construction

Bench Brewery in Beamsville — Construction of the 2,026 square metre building started in the fall of 2017 with the pouring of cast in place concrete foundations and piers. Standard 25 MPa class F-2 concrete was used for the foundations and 30 MPa was specified for the interior slabs on grade. The project was completed in January 2019.

The architect of record is Raimondo + Associates Architects Inc.; the engineer of record is VanBoxmeer Stranges Antonio Ltd.; the general contractor is Merit Contractors Niagara Ltd.; and the material supplier is Dufferin Concrete – A CRH Company. Additional participants include Dunnville Silo, Euclid Canada and Rankin Construction Inc.

Recent Comments

comments for this post are closed