While mass timber finds its footing in the midrise residential world and some commercial/office niche markets, it is also making inroads into other areas, including the educational sector.

“They (mass timber structures) are prefabricated, energy efficient, eco-friendly, fire resistant, have a small carbon footprint, are economical and they save time in construction,” said Shervin Reyhani, who, on behalf of Wood WORKS! Ontario, gave a webinar presentation on what can make wood an attractive building material in schools and other buildings in the educational sector.

“One of the arguments is that if mass timber is good for offices and businesses, why not for schools and other educational buildings?”

High profile projects in Toronto include a 14-storey academic tower at the University of Toronto’s St. George campus, a 10-storey waterfront campus for George Brown College and the six-storey campus for Centennial College in Scarborough. The Ontario Secondary School Teachers’ Federation also selected the material for its new Toronto headquarters now under construction.

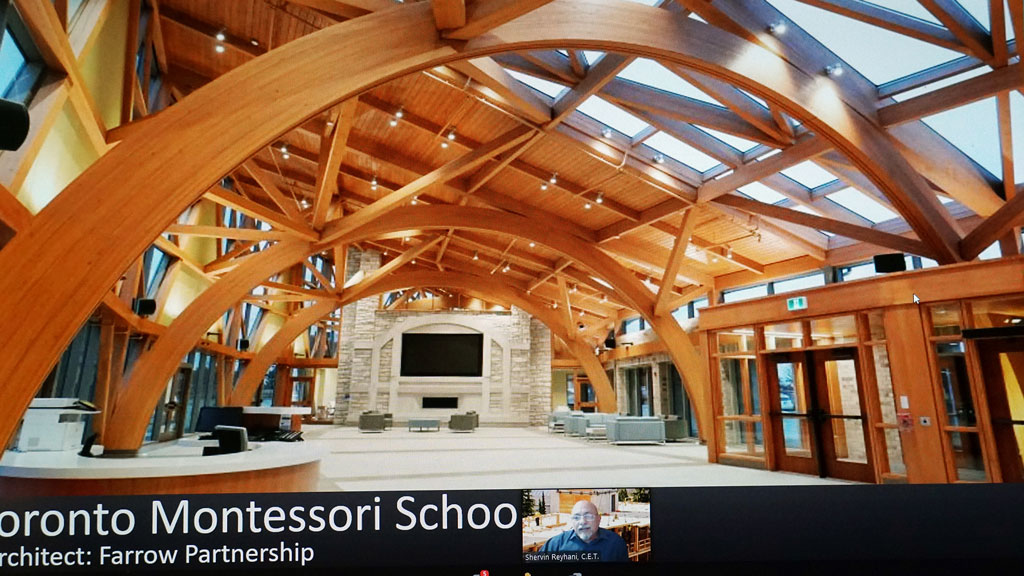

On a smaller scale, mass timber is catching on in the private school sector, with several Montessori schools turning to timber designs in Toronto and elsewhere in Canada.

“Sustainability, effectiveness and efficiency,” are reasons the product’s future looks bright, said Reyhani, who is technical manager of the Canadian Wood Council and Wood WORKS! Ontario.

Speed of construction — an area where mass timber excels — is a particularly important factor in school agendas where tight project timelines are the norm, he said, citing an example of a five-storey, 50,000-square-foot mass timber school in B.C. that was constructed in only nine months.

Reyhani added “solid wood modules” produced by mass timber manufacturer Nordic Structures for example are gaining traction in school construction and for affordable housing types. Along with being cost-effective, the prefab modules are “fast, durable, turnkey solutions for urgent needs in school infrastructure.”

Another reason for specifying mass timber for schools is that research has shown wood interiors help to reduce occupant stress and anxiety.

“Current studies show classrooms designed in biophilia immensely improve test scores (of students)…and increase learning rates.”

Wood also minimizes signal interference for WiFi, said Reyhani, who has worked in the light wood design and manufacturing industry for 33 years.

Introduced to the mass timber world about five years ago, he said as the industry matures new ways are continually being discovered on how to pare costs, sometimes through hybrid designs comprised of mass timber, with light wood frame systems or steel and/or concrete.

A key to the sector’s growth is collaboration between designers, owners and mass timber manufacturers, the latter of which can find cost-reductions through fabrication methods that maintain structural integrity and architectural goals, Reyhani told the webinar.

He said a growing manufacturing base in Canada — and in Ontario — will help assure a ready supply of product at a controllable cost. Along with Element5’s new CLT fabrication plant in St. Thomas, Ont., another CLT fabrication facility is in the works in Parry Sound.

While a few years ago most contractors were unfamiliar with mass timber erection, Reyhani said today a number of builders recognize the product and its assembly/erection methods thanks in part to the Canadian Wood Council’s relationship with mass timber manufacturers and construction training groups such as the Carpenters’ District Council of Ontario provides carpenters.

Once the pandemic recedes and the prices of lumber start to stabilize again, Reyhani believes more builders will turn to timber designs.

“They have been using lightwood frame (in the past), this is no different…it is as easy to work with.”

In the next five or so years, he expects most contractors will understand assembly methods.

“I would have to say there should be absolutely no problem with the installation of any type of (mass timber) product.”

Recent Comments

comments for this post are closed