The fact regulators weren’t sure whether to consider the MULTI an elevator or a train is a testament to just how revolutionary ThyssenKrupp’s new people moving system has proven to be.

The new system employs cars that move passengers both vertically and horizontally along an intricate track system.

The potential for the new system is enormous. Free of ropes and cables, MULTI can serve buildings of any height.

“The original limitation to tall buildings was that there were no elevators,” says Michael Cesarz, CEO of MULTI. “Otis invented the elevator more than 160 years ago and that allowed us to create buildings of 300 to 400 metres tall. After that height, the efficiency of a traditional elevator suffers.”

The world’s tallest buildings need to support increasingly heavy cables required to lift elevator cars.

Because these tall buildings sway considerably, elevators must be designed to protect the cables that might otherwise make contact with the inside of the shaft.

“MULTI is groundbreaking in that it can enable buildings to be built to any height,” says Cesarz.

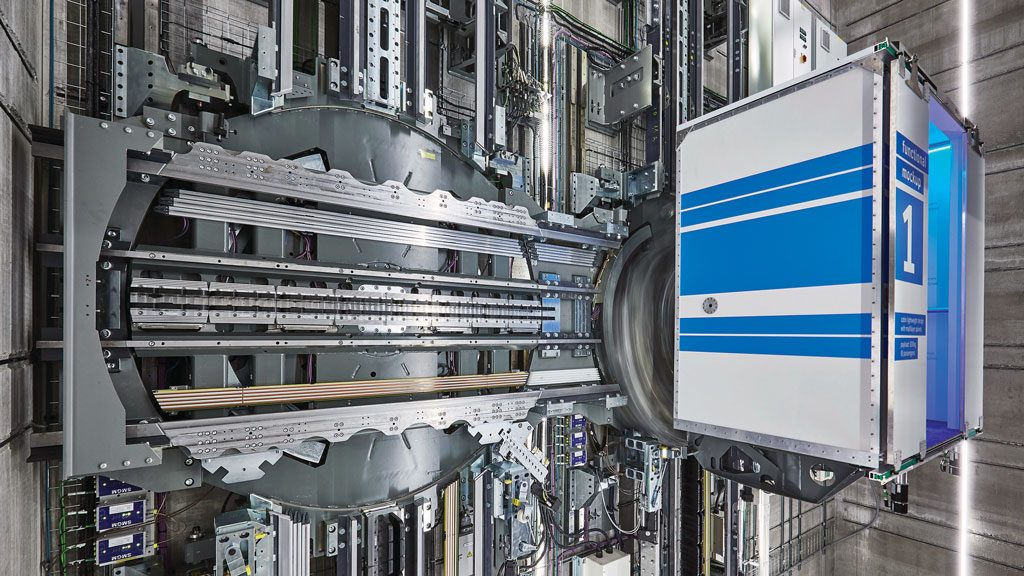

The MULTI track system isn’t electrified. Linear motors attached to the back of each cabin are powered by electromagnetic coils embedded in the rear wall of the shaft.

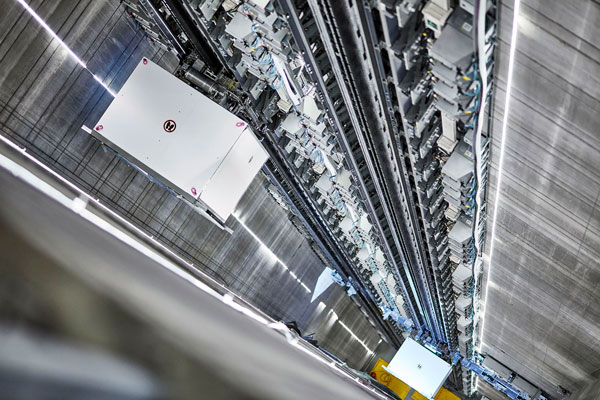

Passenger cabins can move along vertical express routes, then pivot horizontally to allow passengers to disembark while other cabins pass. A purpose-built algorithm directs cabins along optimal routes and ensures they never collide.

Because multiple cars can share the same shaft space, the amount of real estate lost to elevator infrastructure can be reduced by as much as 25 per cent per building.

“The shaft space required to run the cars is smaller,” says Cesarz. “But the real space saving occurs because you simply don’t require as many shafts to serve a building. Depending on the height of the building, you can operate 10 or more cabins in a single shaft.”

ThyssenKrupp designed and installed the 71 traditional elevators in New York City’s Freedom Tower. Had MULTI been available for the project, the company estimates it could have reduced the number of shafts to between 45 and 50.

Cesarz says the capital costs of a MULTI installation would be significantly higher than a traditional elevator, but the costs could be more than offset by the reduction in the number of elevator shafts.

Developers could monetize that additional floor space or build smaller buildings offering the same floor space. MULTI passenger routes could also be extended to neighbouring buildings in the same development via sky bridges outfitted with the track system.

The system offers additional advantages.

Tenants in a building outfitted with MULTI could use an app on their phone to call a cabin that recalled their favourite floor destination. Passengers using elevator controls would be directed to take the cabin that would deliver the largest number of passengers to their destination in the shortest time possible. Companies could also reserve particular cabins for their own employees and clients.

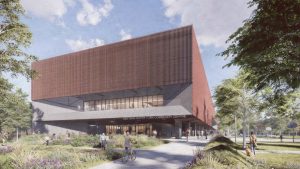

MULTI has been tested at ThyssenKrupp’s 248-metre test tower in Germany where the dividing walls between three adjoining traditional elevator shafts were removed to install the system. The system has since been certified for Germany and is already slated for installation in OVG Real Estate’s East Side Tower Berlin.

Certification for countries outside of North America is expected by mid-2020. The separate certification required for Canada and the U.S. has already been initiated, with certification expected as early as mid-2022.

“What’s taken some time for regulators is to decide whether they’re being asked to certify a train or an elevator,” says Cesarz. “MULTI actually exhibits characteristics of both, but if it’s a train, we would need to apply to a different certification authority.”

Following widespread adoption in new projects, ThyssenKrupp has additional plans for the system.

“After those installations, we will be looking at the potential for retrofitting MULTI into existing elevator shafts,” says Cesarz.

Recent Comments

comments for this post are closed