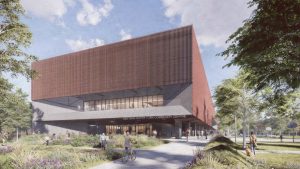

A new prefabricated modular solution developed by WZMH Architects could help rebuild war-torn Ukraine as well as change the way buildings are constructed in urban areas around the world.

The architectural firm and its research and development lab Sparkbird teamed up with industry partners Spring Valley Corp, Stephenson Engineering Ltd, Quasar Consulting Group and Argentum to create a prefabricated, modular, precast solution called Speedstac for mid- to highrise residential buildings.

They can be used to construct new buildings up to 30 storeys tall or replace damaged sections of buildings by sliding new residential units into the existing building.

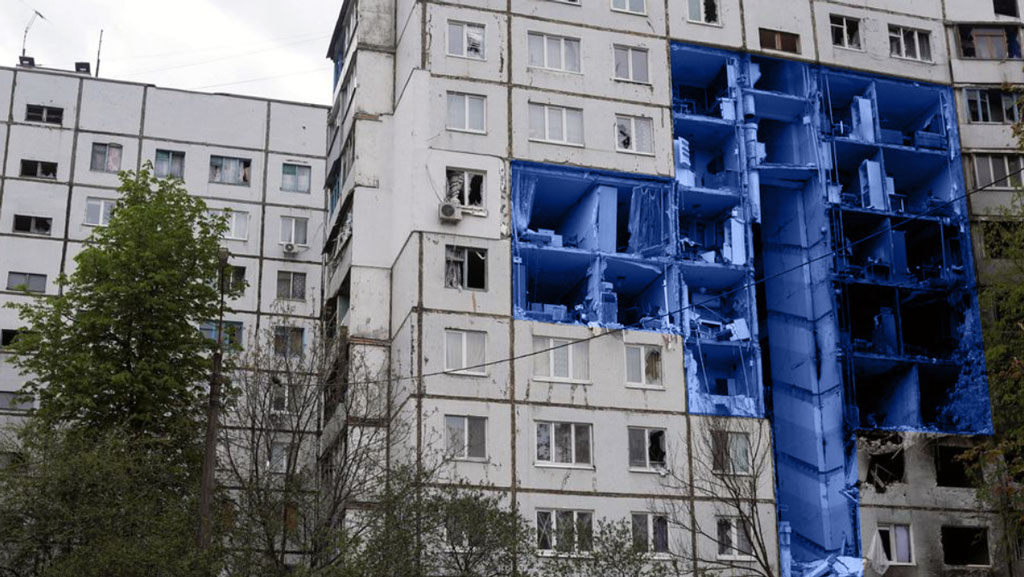

“I think we’ve all seen images on the Internet and in the news of these apartment buildings throughout Ukraine that have been hit by missiles and partially damaged… and fully damaged or fully destroyed,” explained Zenon Radewych, principal at WZMH Architects.

“We were looking at our Speedstac solution, looking at those images and realized, ‘hey, wait a minute. We could probably go to some of those buildings and remove the portions that have been damaged… and basically then reinsert our Speedstac modules and repair these buildings and quickly get them back up to where they were pre-war.”

When the war broke out in Ukraine, a group of Ukrainian architects who temporarily relocated to Canada joined the WZMH team.

They were working on the Speedstac solution for North America and realized it can be applied anywhere, including to rebuild their homeland.

“It’s very much a collaboration between Canadians and Ukrainians,” Radewych said. “We’re collaborating with a number of Ukrainians in Ukraine, engineers and architects that are helping us.”

According to the Embassy of Ukraine in Canada, over 121,000 buildings have been either fully or partially destroyed, indicates a WZMH release.

The concept has been endorsed by the embassy and WZMH said a number of parties have expressed interest in North America, Europe and the Middle East. The units are concrete boxes that are stacked together side by side and on top of each other.

The solution is designed to significantly reduce applied finishes such as gypsum board, carpet, tiles and includes a special sandwich layer that eliminates the need for bulkheads, explained Radewych.

It also features a special connector which facilitates the process of stacking buildings together, speeds up construction times and makes it cost-effective, he added.

“The concept behind these boxes is basically the floor, the walls and the ceiling is made of concrete so it’s durable. It’s great for acoustics and it’s also great for fire resistance,” said Radewych.

Since concrete isn’t green, the team is looking for options to green the boxes.

“We’re using high strength concrete. We’re reducing the thickness of the different members, but we’re also exposing the concrete in a way where it’s the final finish so now you can eliminate different finishes: wall finishes, floor finishes, ceiling finishes and save on those materials,” Radewych noted.

A number of smaller mockups are being put together in the Toronto office. Spring Valley, a precast concrete fabricator manufacturer near Hamilton, Ont., is building a much larger scale mockup out of concrete.

“There is nothing special about it that requires special approvals or needs to be tested,” he said.

“We’ve simply assembled it in a way that makes it unique in terms of how it’s stacked, how it’s connected but it’s made out of the same materials that are used every single day.”

Radewych said testing the connector tolerances is key since 30 modules will be stacked on top of each other and 10 to 15 modules will be connected sideways. Another challenge is weight.

Concrete is much heavier than prefabricated steel or wood frame solutions.

“The cranes that we use in North America, called the everyday cranes that they use on most buildings, they would have a problem lifting some of these units,” Radewych explained.

“For a lot of prefab buildings they use different types of cranes and those can lift the units.

“We’ve been looking at how to reduce the weight of the unit and we’re doing that by reducing the thickness of the concrete where we can and using lightweight concrete.”

One thing the team has done is removed the balcony component from the module and created a separate balcony module.

“On most residential buildings in North America the balconies are poured as part of the floor structure and there really is no thermal break between the balcony and the interior slab,” Radewych said.

“We actually created a solution where our balconies clip on to the edge of the Speedstac unit and there is an actual thermal break between the balcony and the interior slab. What turned out to be a solution to reduce the overall weight of the actual modules has resulted in a great building science solution.”

Follow the author on Twitter @DCN_Angela.

Hi, I like this concept. Have you looked into CLT as an alternative to green the modular? It can also provide some additional R values and reduce thermal bridges.