Winnipeg’s North End Sewage Treatment Plant project, recognized as one of the largest, most complicated sewage treatment upgrade projects in North America, is beyond a mere megaproject – it’s three megaprojects in one.

Funding, procurement, execution and commissioning looked to be so complex that in February 2019, Winnipeg City Council approved a request to break the overall project into three separate capital builds: the Power Supply and Headworks Facilities component; the Biosolids Facilities; and the Nutrient Removal Facilities.

The headworks job, carrying a price tag of $473 million, got underway alongside existing sewage plant operations in 2021 with completion scheduled for 2025.

On Aug. 16, three levels of government announced joint spending of $550 million for the new-era biosolids plant, to be built in a greenfield over six years with a targeted start-up date of 2023 or 2024.

The nutrient removal facility, which has been budgeted at $828 million with no source of funding yet identified, has a hoped-for procurement, construction and commissioning timetable of 10 years or less.

Total estimated cost: $1.85 billion, spread between three governments.

Attending the Aug. 16 funding announcement, Manitoba Minister of Municipal Relations Eileen Clarke said, “This is a monumental project that will have an impact on thousands of current and future Manitobans living in the capital region and beyond.”

Besides replacing inadequate century-old infrastructure, the upgrades will protect waterways by reducing unwanted wastewater and solid flows and improve the city’s treatment of wet weather flows.

“When you put three megaprojects together, there’s that much more complexity,” said Cynthia Wiebe, the city’s manager of engineering services. “You know, scheduling, risk, cost, risk management. It really was a lot of conversation, planning, logistics.”

Key participants in phase one include KGS Group, owner’s consultant, power supply upgrade; AECOM, owner’s consultant, headworks; Black & Macdonald, design-build contractor, power supply; Red River Solutions (Aecon/Oscar Renda/Hatch JV), headworks contractor; KGS and the city, power supply construction manager; Aecom and the city, headworks construction manager.

The city and its owner’s consultants decided to procure via design-build, allowing work to launch after only about 30 per cent of the headworks was designed and enabling continued design fine-tuning as the work got underway, Wiebe explained.

Unlike design-bid-build, in design-build the engineer and the contractor are in communication as a team, having conversations about constructability with reality checks taking place as the project proceeds.

“Because they’re integrated, they may start construction in one area versus a different area because really, what matters is the overall schedule and the overall cost and it gives them a lot more opportunity to innovate within the framework,” said Wiebe.

One example of innovation emerging from the collaboration was the decision to use a jet grouting system to stabilize the soil during excavation on the headworks job, versus a more traditional deep watering system, Wiebe noted.

Breaking the project into three also permitted precision of risk allocation, she explained. There was significantly more soil contamination than was anticipated, a risk that remains with the owner, Wiebe said.

“Knowing ahead of time that you’re going to have to be agile, you’re going to have to deal with these things and creating that kind of a framework and that mentality, and that culture of collaboration, really does go a long way.”

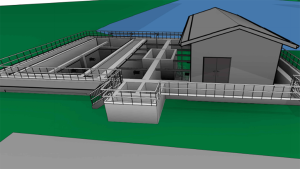

The headworks facility will include a raw sewage pump station, a grit removal system, a micro-tunnel extension of existing interceptor sewers, fine screens and compactors and a plant emergency generator facility. All will be built while the existing facility remains in operation.

With almost every component, Wiebe said, the technology being introduced is a generational improvement on what might have been considered just 15 years ago.

“We’re meeting some tough criteria. We’ve got top-of-the-line grit screening, for example; the grit removal system is a very high efficiency system to remove fine particles,” said Wiebe. “It’s among the best available technologies around right now.”

As for the biosolids plant, years back the end product might have had limited usage. Phosphorous, a non-renewable resource that is being depleted worldwide, will be recovered from the biosolids using equipment and technologies developed by Ostara. The end result is a high value fertilizer called Crystal Green.

“It’s a very marketable product. So we really are building something great for the future, that’s going to allow us to have the biggest impact beneficially in the environment.”

Follow the author on Twitter @DonWall_DCN.

Recent Comments

comments for this post are closed